Metamerism Nightmare: How to Diagnose and Fix Colors That Change Under Different Lights

You've just approved a beautiful brand color match in your viewing booth under D50 daylight. It looks perfect on the press sheet. Then the packaging hits the retail shelf under LED store lighting—and suddenly the blue looks purple, the red looks dull, or the green shifts to brown. Customers notice. Buyers complain. Rejections follow.

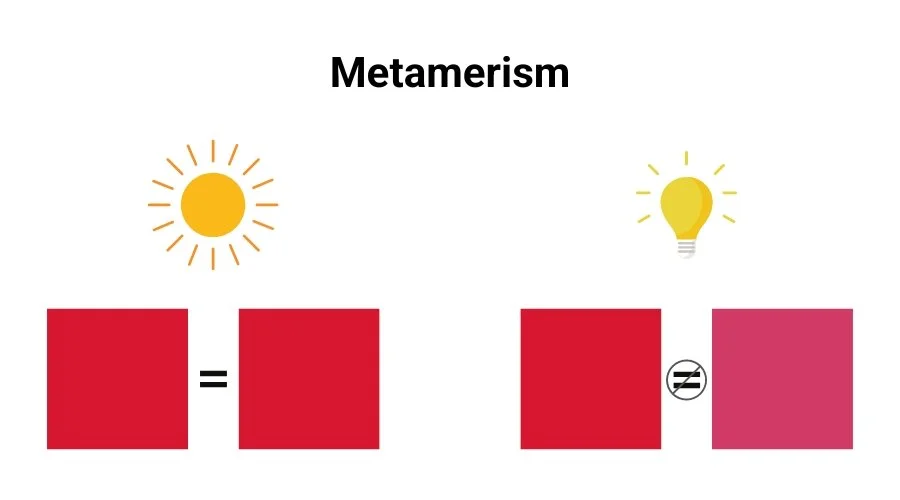

This is metamerism—the "nightmare" phenomenon where two colors appear identical under one light source but differ dramatically under another. In packaging, it's one of the most frustrating and costly issues, especially for brands sold across diverse retail environments (big-box stores with mixed LED/fluorescent, warehouses, online photos, etc.).

The good news: metamerism can be diagnosed early and minimized (or even eliminated) with the right tools and processes. Here's a practical guide for printers and brand teams.

What Is Metamerism and Why Does It Happen?

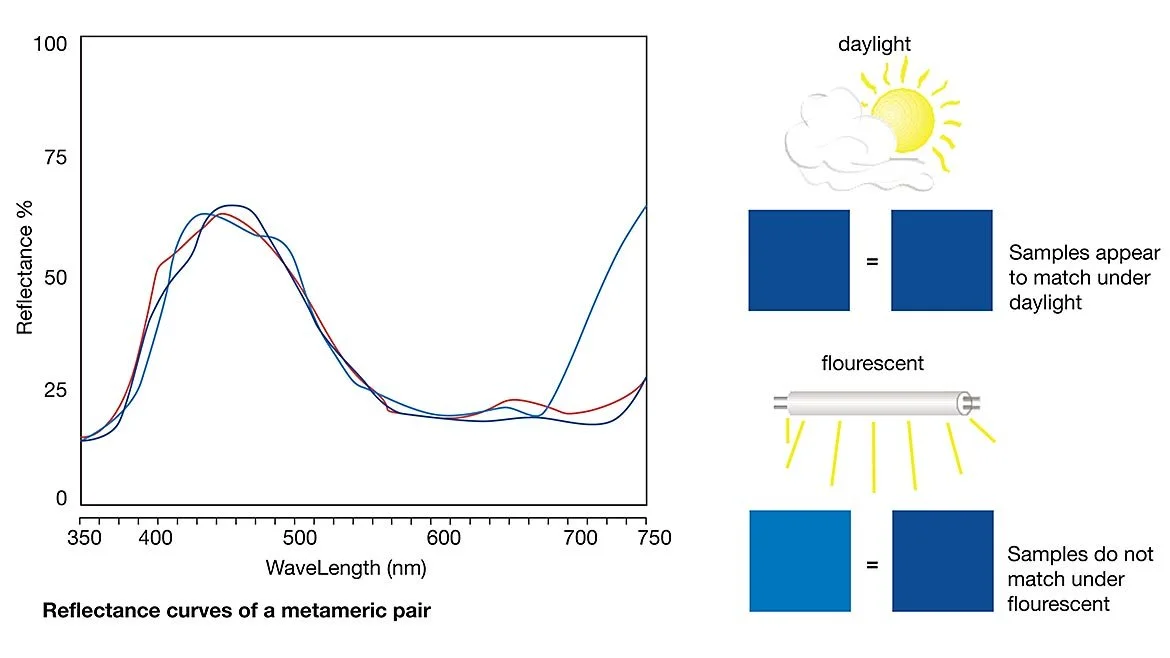

Metamerism occurs when two materials have different spectral reflectance curves but reflect light in such a way that the human eye perceives them as the same color under specific illuminants. The human visual system relies on three cone types (short, medium, long wavelength—blue, green, red sensitivity), and different combinations of wavelengths can stimulate the cones identically under one light but not under another.

For example, two blues might match under daylight (D65) but diverge under warm LED or fluorescent (F11). In packaging, this often arises from:

Different ink formulations (e.g., CMYK vs spot ink)

Substrate variations (paper vs plastic film vs metallic)

Optical brighteners (OBAs) in paper that glow under UV-rich light

Batch-to-batch ink or material differences

How to Diagnose Metamerism Quickly

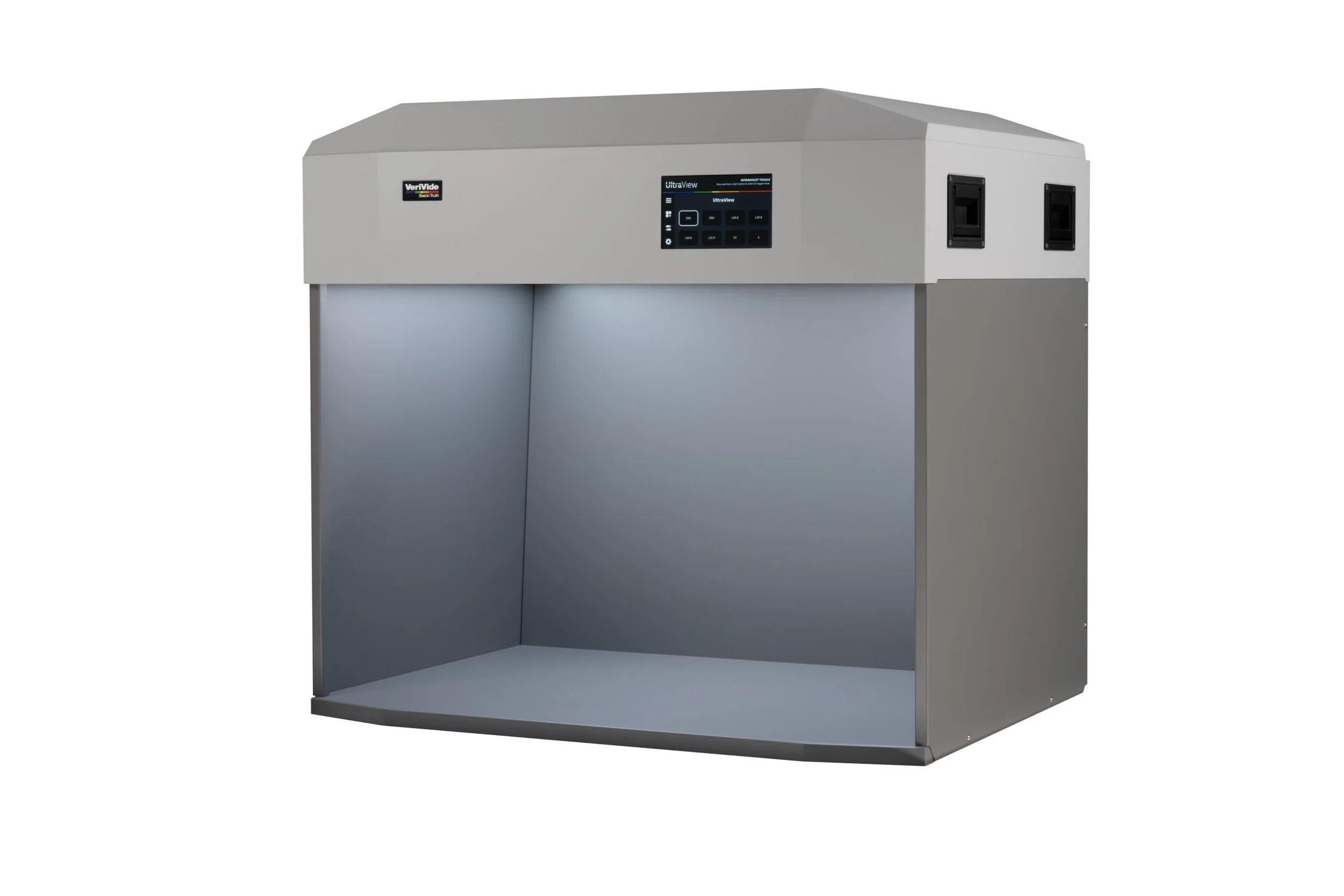

Use a Multi-Illuminant Viewing Booth The fastest, most reliable way to spot it is with a standardized light booth that simulates common sources: D50/D65 (daylight), TL84 (store fluorescent), LED (modern retail), A (incandescent), UV (for OBA check).

View samples side-by-side under each light.

If the match holds under all relevant sources, you're good. If not, metamerism is present.

Measure with a Spectrophotometer

Take spectral reflectance data (full 400–700 nm curve) of both samples.

Compare curves: If they cross multiple times (common in metamers), they're likely to shift under different lights.

Calculate Metamerism Index (MI) using CIE standards (e.g., MI for D65 vs A). Values >1 indicate visible mismatch.

Visual + Instrumental Combo Don't rely on numbers alone—always confirm visually under target lights. Use tools like X-Rite eXact or Konica Minolta CM-36dG for both spectral and Lab data.

Proven Ways to Fix or Minimize Metamerism

Specify Colors Using Spectral Data (Not Just Lab or RGB)

Brands should define colors via spectral reflectance curves (e.g., in PantoneLIVE or custom libraries).

This ensures printers match the full spectrum, not just tristimulus values that can hide metamerism.

Use Low-Metamerism Ink Formulations

Work with ink suppliers (e.g., Sun Chemical, INX, Flint) to select formulations designed for low metamerism.

Avoid heavy reliance on OBAs in substrates—opt for OBA-free or controlled papers.

Match Under Multiple Illuminants from the Start

Require approval under at least two key lights (e.g., D50 for press, LED or TL84 for retail).

Use contract proofs on the actual substrate and view under simulated store conditions.

Implement G7 or GMI Process Controls

G7 calibration helps stabilize gray balance and reduces overall variability.

GMI certification enforces ongoing verification prints and process controls that catch metameric drifts early.

Choose Compatible Materials and Processes

When possible, use similar ink sets across substrates.

For flexo/digital/offset mixes, profile each process to minimize differences.

Real-World Impact and Prevention

Printers who address metamerism proactively report fewer shelf rejections, faster approvals, and stronger retailer relationships. One client we worked with reduced metamerism-related returns by over 70% after switching to spectral-based specs and routine multi-light evaluations.

Bottom Line

Metamerism isn't inevitable—it's a solvable problem when you move beyond "it looks good here" to "it must look good everywhere." Diagnose with spectral measurement and multi-light viewing. Prevent with spectral standards, low-metamerism inks, and consistent verification.

If metamerism is causing headaches on your packaging jobs, Mann & Co. can help integrate these controls into your workflow—whether through our GMI Printer Essentials program or custom consulting.

Explore our GMI programs or contact us to stop the color shifts before they hit the shelf.