Maintaining GMI Compliance After Certification: Monthly Checks You Can’t Skip

Congratulations—you’ve earned GMI certification. Your packaging print facility is now approved to supply major retailers like Home Depot, Target, CVS, and Walgreens. The doors to premium contracts are open, and your team has proven it can deliver consistent brand color, print quality, and process reliability.

But certification isn’t a finish line; it’s the starting gate. GMI (Graphic Measures International) certification requires ongoing compliance to stay in good standing. Drift in process controls, equipment calibration, or measurement protocols can drop your supplier score, trigger reviews, or even lead to certification suspension—costing jobs and shelf space.

The key to long-term success? Disciplined monthly checks that catch issues early. These aren’t optional extras—they’re essential to protect your certification, maintain high continuity scores (Platinum >90%, Gold/Silver 80–89%), and keep retailers confident.

Here’s a practical guide to the monthly (and ongoing) checks every GMI-certified printer should prioritize.

1. Run and Evaluate Verification Prints (Monthly or Per Defined Frequency)

GMI compliance relies on repeatable, measurable results. Regular verification prints confirm your process hasn’t drifted since certification.

What to do: Print a standard verification form (often based on your original GMI test kit elements or a simplified control target) on key substrates and presses.

Key measurements:

Solid ink density (SID)

Dot gain / TVI

Gray balance (per G7 principles if applicable)

Brand spot colors (Delta E against reference)

Overprint trapping

Frequency: At minimum monthly on primary production lines; more often for high-volume or variable jobs.

Action: Log results in your quality system. If any parameter exceeds tolerances, investigate root cause (ink, anilox, substrate, press settings) and correct before production runs.

Why it matters: Ongoing sample evaluations feed your continuity score—the metric GMI uses to rank you. Consistent high scores keep you in Platinum or Gold status.

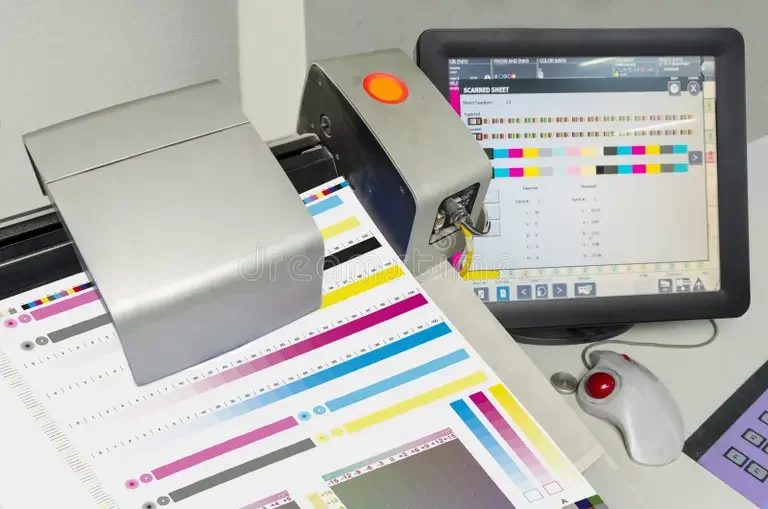

2. Calibrate and Verify Measurement Instruments (Monthly)

Your spectrophotometer is the heart of compliance. Even slight calibration drift can make good prints look bad (or vice versa) in GMI evaluations.

Monthly routine:

Calibrate your device (X-Rite eXact, Konica Minolta, etc.) using certified white/black calibration tiles.

Run a verification check against a known reference standard.

Document date, operator, and results.

Tip: Schedule calibration on the first of every month—make it non-negotiable.

Consequence of skipping: Inaccurate measurements lead to false passes/fails, rejected submissions, and score drops.

3. Audit Process Controls and Documentation (Monthly Spot Checks)

GMI evaluates five core areas: process control/documentation, equipment maintenance, training, operator capability, and equipment performance. Drift in any can jeopardize compliance.

Quick monthly audits:

Review SOP adherence for color matching, press makeready, and quality checks.

Check preventive maintenance logs (anilox cleaning, plate inspection, press alignment).

Verify operator training records—ensure new hires or refreshers are documented.

Scan recent job files for complete documentation (color targets, proofs, approvals).

Use a checklist: Create a one-page monthly audit form tied to your GMI certification requirements. Assign it to a quality lead.

Why monthly? Catching small deviations early prevents systemic issues that show up in GMI sampling or retailer audits.

4. Review GMI Sample Submission History and Continuity Score

GMI monitors ongoing production via random or required sample submissions for retail private brands.

Monthly task: Log into your GMI portal (or review reports) to check:

Recent sample scores and feedback.

Your overall continuity percentage.

Any trends (e.g., recurring failures in trapping or density).

If scores dip: Immediately analyze—often tied to unchecked process drift.

Goal: Stay above 80–90% to avoid "under review" status.

5. Conduct Internal Mock Audits and Lighting Checks (Quarterly, with Monthly Spotting)

Metamerism and visual consistency can creep in over time.

Monthly spot check: Pull recent production samples and view under multiple lights (D50 press, LED retail, TL84 fluorescent).

Quarterly deeper: Run a mini internal audit simulating GMI’s focus areas.

Document: Log findings and corrective actions.

Real-World Payoff

Printers who treat these monthly checks as non-negotiable report:

Sustained Platinum-level scores

Fewer GMI rejections or retailer complaints

Faster approvals on new jobs

Stronger relationships with brand owners and retailers

One folding carton printer we supported maintained 92%+ continuity for over two years by implementing a simple monthly dashboard—verification prints, calibration logs, and quick process audits—all tied to their quality system.

Don’t Let Compliance Drift Cost You Contracts

GMI certification opens doors, but only consistent execution keeps them open. Monthly checks are your safeguard against drift, score drops, and lost business.

If maintaining these routines feels overwhelming or your team needs structure, Mann & Co.’s GMI Printer Essentials program includes clear guidance on long-term compliance, downloadable checklists, and ongoing support to make maintenance straightforward.

Enroll in GMI Printer Essentials or contact us to build habits that protect your certification for years.